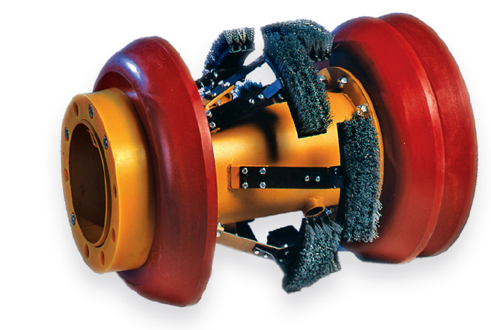

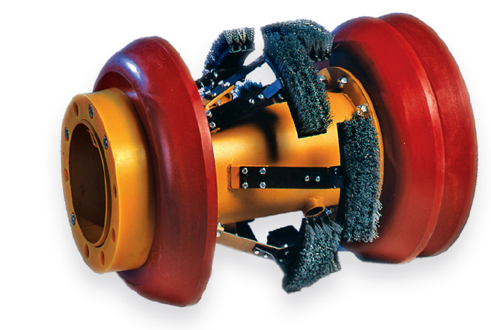

Newly constructed pipelines are pigged to remove construction debris such as welding rods, weld bead slag and mill scale, rust, as well as to remove hydrostatic water. ECCO also supplies pigs used for drying pipelines in preparation for introduction of hydrocarbon products. We understand that not all pre-inspection pipeline cleaning needs are the same, so we carry a variety of solutions catered to specific cleaning requirements. These pigs include: Low-Density Pigs – Used to dry pipelines and remove lite dust. Foam Disc Pigs – Used for removing hydrostatic water and debris Wire Brush Pigs – Used to achieve a high degree of pipeline cleanliness by removing debris that could trap moisture. Gauging Pigs – To confirm that there are no restrictions in the pipeline for future running of cleaning and ILI pigs. This design has an aluminum plate to detect mechanical defect features

Excess Liquids Cause Pipeline Corrosion Corrosion is inevitable within a pipeline, however taking a proactive approach to preventative maintenance can save you thousands, if not millions of dollars in repair, replacement, or environmental clean-up costs. Liquids of any kind can pose risks in both oil and gas pipelines. Low spots in oil or gas pipelines can accumulate liquids (condensate or water) causing a breeding ground for bacteria that can cause pitting of the pipeline wall. What is Pitting Bacteria? Because water is heavier than oil, water settles in low evolutions of the pipeline route. If a corrosive component in the production fluids is present, the low areas of the pipeline have the most potential for pitting bacterial to form. How Pipeline Pigging Can Prevent Pitting Bacteria? Periodic pigging is an effective and efficient way to prevent standing liquids from compromising the integrity of a pipeline. A pigging program that includes the use of pigs with heavy duty bristles and pit cleaning brushes are highly effective in both swiping the liquids downstream, and out of pits. Removing the liquids from the pits allows the pipeline wall to more adequately accept biocides to treat bacteria corrosion.

What is Black Powder? Black powder consists of iron compounds including magnetite (mill scale), iron sulphide, sand, clay, salt, weld slag and even iron. The powder is created during gas production, or in wet gas pipelines where hydrogen sulphide, carbon dioxide or oxygen are present in the gas, or by bacterial corrosion of the steel. These deposits are normally black in color and can be in a dry, dust form or wet when combined with hydrocarbon liquids, compressor oils, etc. The powder is then distributed through the pipeline with the gas flow, but is deposited when the velocity is not high enough to keep it moving. As sediment is deposited, the flow in the pipeline is disrupted and reduced, thereby allowing more sediment to accumulate. System through puts are affected and energy costs increased to maintain design flow rates. Blockage can occur especially during cleaning and damage caused to plant such as compressors. How can ECCO Services help? Black powder is a significant problem in natural gas pipelines. Helping our clients take a more proactive approach to black powder removal is why ECCO remains an innovator in the pipeline pigging industry. It is essential to remove black powder and clean the pipeline thoroughly prior to running In Line Inspection Tools or “ILI” tools. Costly down time and line failures caused by the powder can be avoided by following a thorough cleaning procedure that includes using a variety of pipeline cleaning pigs. To ensure Black Powder doesn’t become a problem, ECCO can assist in developing a comprehensive pigging program to help avoid the potential for blocking the line or having to deal with large volumes of debris after cleaning.

What Causes Wax & Paraffin in Pipelines? Crude oil and gas condensates contain varying amounts of wax or paraffin. When oil is at 60 to 70°c, the wax is dissolved, but as the temperature drops below 35–40°C, wax solidifies onto the walls of the pipe, causing roughness, turbulent flow and diameter restriction that reduces product flow. The wax can become extremely hard on the wall of the pipe through time, especially with static flow and temperature changes during maintenance shutdowns. ECCO Provides Waxy & Paraffin Removing Pigs ECCO with our Partner Kleiss offers pipeline cleaning pigs with cleaning agents specifically made to effectively remove wax from the line by keeping it suspended in the product flow ahead of the pig. Keeping the wax ahead of the pig is key to avoiding damage to valves. Our pigging experts can assist you in designing a pigging program to prevent the build up of wax and paraffin in your lines.

We offer top-notch services based on countless years of experience.

Newly constructed pipelines are pigged to remove construction debris such as welding rods, weld bead slag and mill scale, rust, as well as to remove hydrostatic water. ECCO also supplies pigs used for drying pipelines in preparation for introduction of hydrocarbon products. We understand that not all pre-inspection pipeline cleaning needs are the same, so we carry a variety of solutions catered to specific cleaning requirements. These pigs include: Low-Density Pigs – Used to dry pipelines and remove lite dust. Foam Disc Pigs – Used for removing hydrostatic water and debris Wire Brush Pigs – Used to achieve a high degree of pipeline cleanliness by removing debris that could trap moisture. Gauging Pigs – To confirm that there are no restrictions in the pipeline for future running of cleaning and ILI pigs. This design has an aluminum plate to detect mechanical defect features

We develop comprehensive PPC and SEO strategies. We’ll provide your AdWords account with continuous PPC support that is monitored to adapt to the evolving industry.

Need a place to add in your awards? This is it. Want to include more information about your products, history, or features? This is the spot for that. Use this content section for anything and everything.