ECCO’s PROVIDE A COMPLETE INSPECTION SERVICE INCLUDING MANAGING INSPECTION PROGRAMMES, AS WELL AS CONVENTIONAL AND ADVANCED NDT SERVICES; SUPPORTING ASSETS AT ALL STAGES OF THEIR LIFECYCLE. We offering NDT facilities combined with our long standing expertise. With vast experience and knowledge in both large and small scale Inspection and NDT projects. Our company have a highly skilled team of Engineers & technicians ertified inspectors PCN (EN ISO 9712) & ASNTthat operate7/24 and are readily available to advise on the best method possible for your project. Our service portfolio includes: - Third Party Inspection - Visual Inspection - Magnetic Particle Inspection - Dye Penetrant Inspection - Ultrasonic Inspection - Radiography (X-Ray and Gamma) Positive Material Identi cation (PMI) Testing - Hardness Testing - Hydrostatic Testing - Heat Treatment - Ferrite Testing - Painting Inspection - Machining Surface Roughness Inspection - General QA/QC services as per international codes and standards (ASME, AWS, EN…......) - WQT Welders qualifications. - Preparation of WPS, PQR. - API in-service inspection (API 570, API 653 & API 510) - Preparation of ASME review manual & procedures. Our approach in terms of fabrication related NDT, is to provide our clients with the option of an integrated service, where Radiography (or alternative methods), Hydrostatic Testing and Heat Treatment services can all be provided under the one roof, avoiding the requirement for clients to engage with multiple vendors.

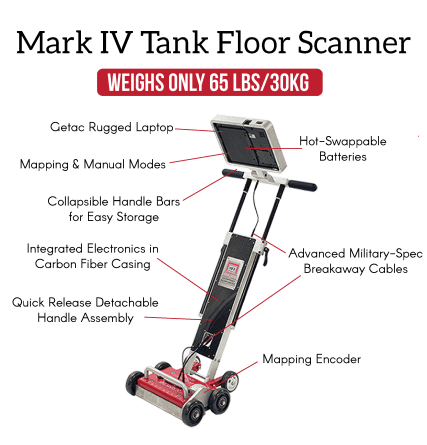

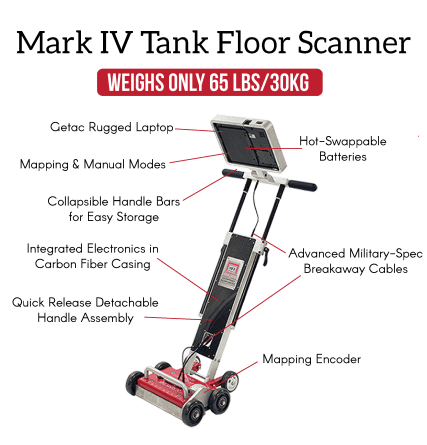

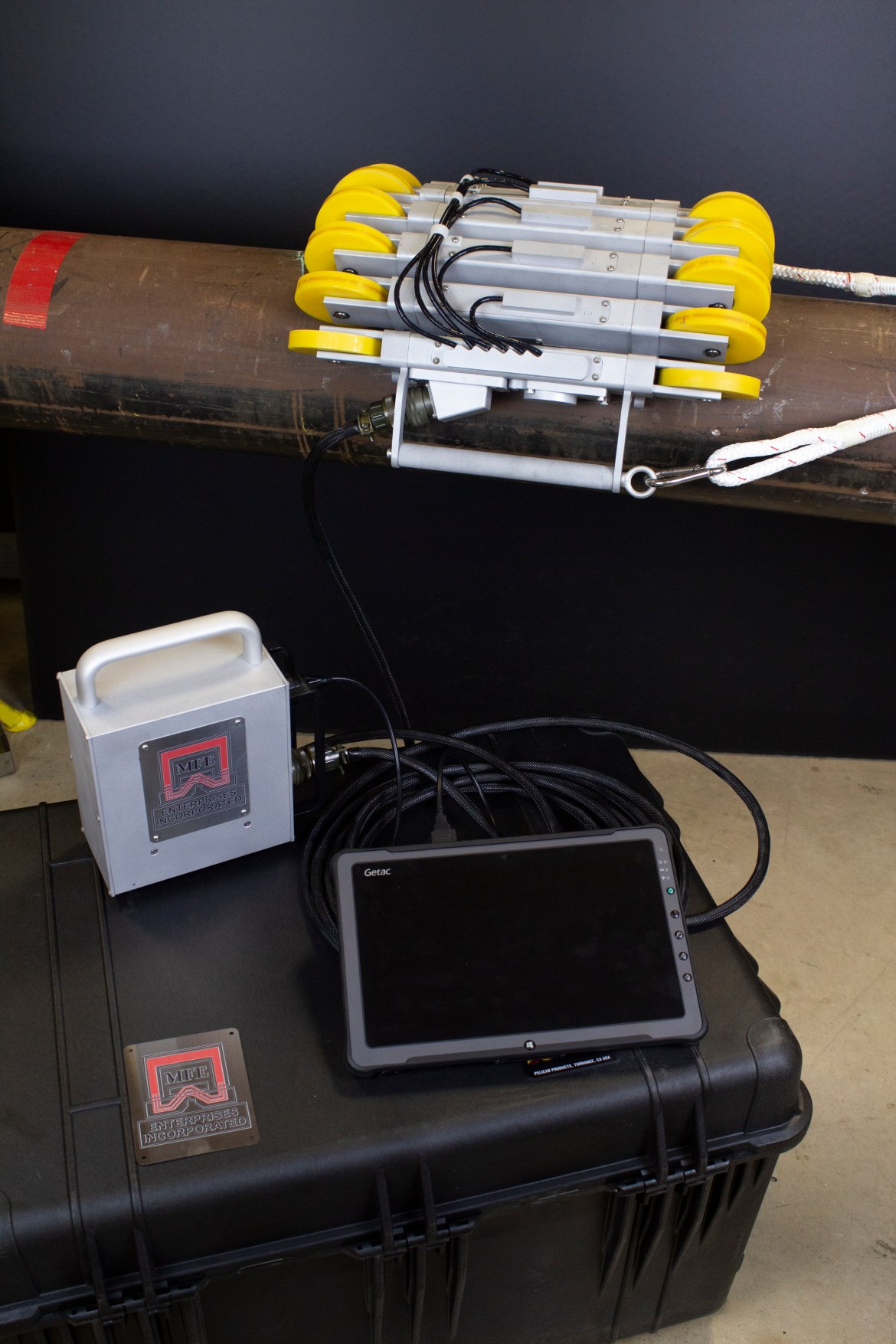

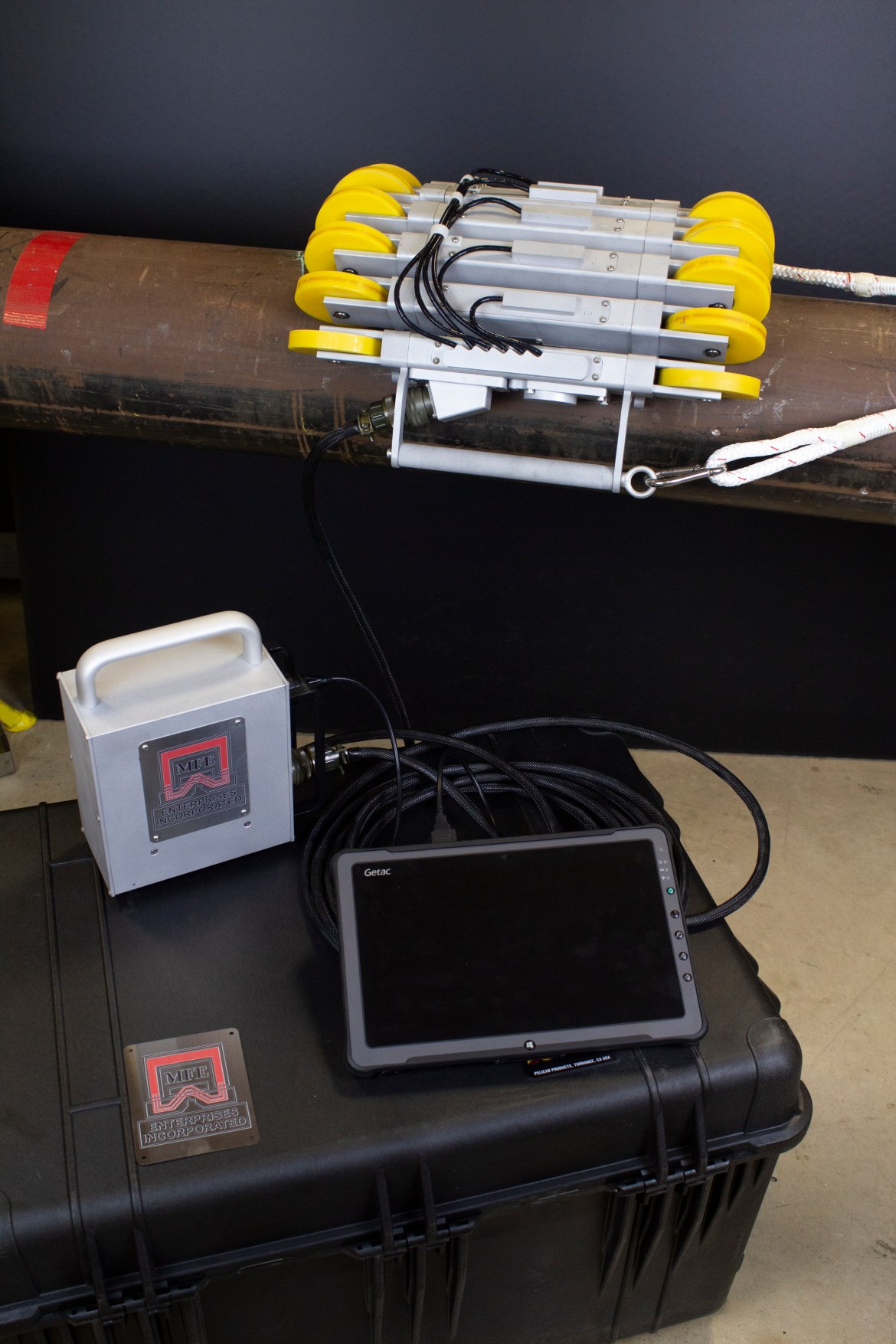

PHASED ARRAY ULTRASONIC TESTING (PAUT) INSPECTION SERVICES Phased Array Ultrasonic Testing (PAUT) is a focused inspection technique designed to incorporate beam technology to detect complex geometries & sizing defects. ECCO’s Phased Array (PA) inspection services are an accurate, efficient, and reliable volumetric examination technique offering real-time imaging to reliably detect and measure corrosion, cracking, flaws, and other defects across a wide variety of materials, components and industries MFL Tank Floor Scanner MARK IV PIPESCAN pipe scanner can inspect pipes with a diameter of 5” and up at a speed of up to 3 feet per second. PipeScan is capable of scanning through thin coatings to detect water, fuel and chemical leaks. View digital volume loss signals in real-time on the included Getac Tablet display. HSR Crawler The HSR Crawler (High-Speed Raster) is an innovative ultrasonic scanner that addresses the need for an automated raster type unit offering higher performance and durability over an extended range of applications. The scanner traverses large vessels with obstacles that are problematic for most tank crawlers, yet performs corrosion scanning on pipe down to 2 nominal diameter while requiring no probe adjustments over the range. Jireh Tripod Wall Crawler The Jireh Tripod Wall Crawler is a remotely controlled vehicle designed to move along straight or curved metal surfaces. Using three powerful magnets, the wall crawler can climb vertically or horizontally, even upside down. Cameras and other inspection equipment can also be attached, allowing for easy access in hard to reach places. Jirah’s Tripod Wall Crawler has a three wheeled computerized drive system, providing 360 degree rotation, giving you unparalleled movement and flexibility.