Third Party Inspection

Our services offer third-party inspection services to meet your statutory compliance either as a planned process or in an emergency situation.

Third Party Inspection confirmation, verification and inspection services to one or more internationally recognized codes, standards, design specifications and specific technical project requirements.

We have a wide range of inspection plans to suit your need, and our experts have the experience that comes from extensive documentation and inspection activity.

Third Party Inspection

Oil and gas, power generation and distribution

Water treatment

and distribution

Pipelines, Refineries, Chemicals and petrochemicals

Mining

Infrastructure, Telecom, Transportation

Infrastructure, Telecom, Transportation

Non Destructive Testing

Having the right systems, processes and procedures ensures consistency that is critical in complying with relevant codes,

requirements, regulations and standards.

ECCO’s end-to-end approach to inspection factors in accountability, consistency and compliance at every stage.

ECCO’s PROVIDE A COMPLETE INSPECTION SERVICE

INCLUDING MANAGING INSPECTION PROGRAMMES,

AS WELL AS CONVENTIONAL AND ADVANCED NDT

SERVICES, SUPPORTING ASSETS AT ALL STAGES OF THEIR LIFECYCLE.

We offering NDT facilities combined with our long standing expertise.

With vast experience and knowledge in both large and small scale Inspection and NDT projects.

our specialists are also certified in accordance with ISO 9712, PCN, SNT-TC-1A.

That operate 7/24 and are readily available to advise on the best method possible for your project

Our service portfolio includes

Surface methods (visual testing, magnetic particle testing, penetrant testing, and hardness testing)

Volumetric methods (radiographic testing, ultrasonic testing)

Phased Array Ultrasonic Test (PAUT)

Inspection Technique:

Phased array is an advanced pulse-echo technique utilizing multiple miniaturized transducers and time-delays to shape

the ultrasonic sound beam in a desired angle and focus.

Therefore the technique has a wide range of applications.

A phased array probe houses an array of ultrasonic transducers which are acoustically insulated from each other.

By pulsing the elements with different time-delays,

the angle of the ultrasonic sound is ‘steered’ to

a specific angle, focus-point or both.

Phased array has several advantages in comparison to manual pulse-echo:

Digital storage of all data, location and system settings, Visualization of indications in weld and/or base material,using B-, C-, D- and S-scans

(with all A-scans included),Possibility to facilitate inspections of complex geometries.

Applications:

With phased array there is a wide range of applications,

such as n Weld inspection of vessels, pipelines and plates

n Weld inspection of complex geometries, such as

nozzle-welds, Flange face corrosion inspection ,

Fast corrosion scanning utilizing 0 degree angled wedges, Code case inspection in combination with Time of Flight

Diffraction (TOFD) and/or pulse-echo.

Positive material identification (PMI)

Positive material identification (PMI) is used to analyze and identify material gradeand alloy composition for quality and safety control

A rapid, non-destructive method, positive material identification is performed on a wide range of components and assets, and provides a semi-quantitative chemical analysis. It is used for both material verification and identification.

The method is utilized for quality control and safety compliance, and is an integral part of both production and asset integrity management across many industries

including oil and gas, power, chemical, pharmaceutical, nuclear, aerospace and fabrication.

Positive material identification can prevent potential product failure in manufacturing.

At oil and gas, power generation and pharmaceutical plants, pre-service and in-service inspection of critical components and welds with PMI can prevent breakdown and its costly consequences.

PMI can:

Ensure products/components have been manufactured using the correct alloy

Find potentially mixed-up alloys

Identify if the wrong material has been used

Ensure material conforms to the correct standard and specification (both customer and industry)

Ensure welded components have used the correct filler material

Portable Hardness Testing

Portable hardness testers for in situ metal hardness measurement

Portable Hardness testers are designed to be compact and easy to use, for fast testing of metal hardness in situ. Save time and take the tester to the job!

Digital type portable hardness testers

Use LEEB rebound or Ultrasonic Contact Impedance (UCI) test method to quickly determine metal hardness.

Results are automatically converted into common test scales such as Rockwell C, Rockwell B, Vickers and Brinell

Mechanical type portable hardness testers

Use an indenter impressor of diamond or steel ball type, similar to those found on a traditional bench-mounted hardness tester.

They are a manual instrument where the user applies the test force using a rotary knob and reading the hardness result on the dial indicator.

We specialise in handheld hardness testers and stock a wide variety of options to suit your application.

Please contact us to discuss your application so we can specify the right tester for you!

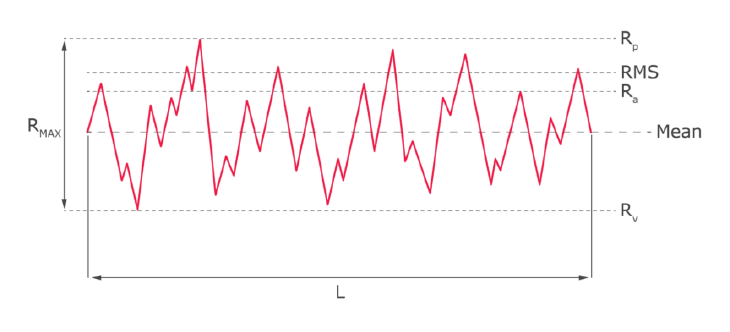

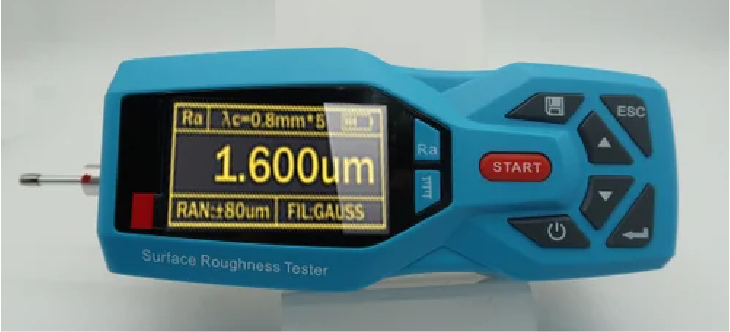

Machining Surface Roughness Inspection

Machining surface roughness is measured using tools like a profilometer or laser scanner to quantify the texture of a surface.

The most common metric is the arithmetic average (Ra), which represents the average deviation of the surface’s peaks and valleys. Other parameters exist, such as total roughness (Rt), which is the highest peak minus the lowest valley.

Surface Roughness Tester is an ideal measuring instrument suitable for use in multiple environment due to its reduced size.

As a portable handheld device, the SR 200 is simple and easy to use, providing the user with fast and accurate measurements anytime anywhere.

The SR200 is capable of evaluating surface textures with a variety of parameters in accordance to various national standards and international standard.

Measurements are displayed both digitally and graphically on the LCD, together with an output for direct transfer to your printer.

A standard coating inspection consists of 6 steps

Once the specification has been written, the application process must be monitored from beginning to end,

from surface preparation to final color and gloss. This process generally consists of six standard steps:

Inspecting the surface preparation and pre-treatment:

The most fundamental phase of a coating inspection.

A well-prepared surface is the foundation of a successful coating.

The aspects to inspect include surface cleanness and roughness.

There are coating inspectors who specialize in assessing surface preparation such as sand blasting.

Assessing climate conditions

Environmental factors such as climate must be assessed to prevent the air, surface temperature, or humidity affecting the curing and adhesion of the coating.

The specification should define the optimal application conditions.

Measuring film thickness (before and after curing)

It is important to inspect the film thickness of powder coatings and liquid coatings before the coating cures so that and deviation from the specification can be detected and repaired before curing.

The dry film thickness is measured to make absolutely sure the film thickness is in accordance the optimal performance of the coating.

Observing the curing rate

The coating must be cured to the degree defined in the specification.

if the coating is not cured enough the surface lacks hardness, making the finished coating layer more vulnerable to hazards such as abrasion and chemicals.

Checking for sufficient adhesion

The current methods of testing adhesion are all destructive, so the test is usually conducted on a sample substrate.

It is crucial that the sample has undergone the exact same treatments under the exact same conditions as the real substrate.

Evaluating the color and gloss of the cured film

The color of a coating needs to match the specification, but also be consistent across the whole surface.

Gloss level is also measured, and checked for deviation

Lifting Inspection

Whether you own or operate cranes, lifting or hoisting equipment, you need to ensure that they are safe, and in compliance with statutory requirements.

That is where our crane, hoisting and lifting equipment inspection can help.

Third-party inspection of lifting equipment refers to the unbiased assessment conducted by specialized external experts, such as ECCO, to evaluate the safety, functionality,

and compliance of various lifting devices.

These devices include cranes, hoists, slings, rigging gear and other lifting accessories.

Third-party inspectors, like us, ensure that these lifting equipment pieces adhere to industry standards, regulations, and safety protocols.

Our services are certified by the Lifting Equipment Engineers Association (LEEA), underscoring our commitment to the highest global industry standards.

Advantages of Third-Party Inspection

Assessing climate conditions

Verification of lifting equipment’s quality and adherence to industry standards.

Enhanced Safety

Identification and mitigation of potential hazards, ensuring a safe working environment.

Regulatory Compliance

Assurance that the equipment meets local and international regulations, preventing legal issues.

Risk Reduction

Minimization of operational risks and accidents through thorough inspections and preventive measures.

Reliability

Assurance of equipment reliability, leading to reduced downtime and maintenance costs.

Improved Efficiency

Well-maintained equipment operates efficiently, enhancing overall workplace productivity.

Earthmoving Equipment Inspection

Earthmoving equipment, such as excavators, bulldozers, loaders, and graders, are crucial for various heavy-duty operations.

We understand the importance of maintaining the integrity and functionality of these machines to ensure safe and efficient work on construction sites or mining projects.

Our certified inspectors have extensive knowledge of earth moving equipment and industry regulations.

Safe and quality earthmoving equipment with our heavy machinery certification

To ensure reliable service and protect workers in risky environments, manufacturers of heavy machinery around the world must be certain that all applicable statutory requirements and safety standards are met without exception.

Ensure reliability of your heavy equipment – and protect workers’ safety

Our experts certify your equipment safe and reliable to ensure your customers quality and compliant products they can depend on to protect workers, lower liability and reduce any risk of malfunction that could cause costly downtimes.

WELDING QUALITY SERVICES

We offer a complete welding support service from weld procedure writing to welder qualification, third party welder witnessing and destructive and non-destructive testing.

Our Expertise:

ECCO’s welding services support customers in a diverse range of industries, all of whom share similar challengers in meeting quality, safety and compliance requirements.

We provide highly qualified and experienced personnel who understand the processes involved in the supply chain and the frequent need for speedy turnaround times.

Our experienced welding personnel have IWE, PCN and CSWIP qualifications.

They ensure our customers’ quality control, weld procedures and welder certifications comply with industry recognized international and national standards.

They can work on-site within our customers’ premises.

Weld and Welder Qualification:

ECCO offers writing of welding procedures and welding certification to British, European and American welding standards.

Our welding experts provide consultancy and certify welders to national and international standards.

ECCO supports firms in industry sectors such as construction, fabrication, automotive, rail and power generation.

Third party witnessing and invigilation can be provided at your workplace. We also offer a visual inspection of weld course to BS EN 5817 level C.

Responsible Welding Coordinator:

CE Marking for structural steel became mandatory for products sold on the EU construction market as of July 2014.

This means that all companies manufacturing or supplying structural steel for use in EU are required to have a documented welding

quality management system in place and will need to either employ or have access to a RWC.

The role of the RWC is to control and supervise all welding activities, and to ensure the steel structures meet the required levels of mechanical strength, stability, serviceability

and durability.

Many companies may not have the requirement for a full-time RWC. ECCO can supply the services of our qualified welding experts to act as your RWC to help your in house personnel monitor and control your welding activities.